Butyl Rubber Coating Machine

- KING TECH

- CHINA

- 15 DAYS

- 300 sets/ Month

KT-BM Series Butyl extruder for precision Butyl coating on both sides of spacers.

Sensor-controlled guide Rollers ensure optimal stabilization of the frame and thus enable even coating.

Opening and closing of the coating nozzles for each frame side are controlled automatically.

The integrated measurement device for frame widths ensures continuous nozzle adjustment from

6 to 24 mm.

The coating speed can be set individually.

The butyl coating machine with high-precision is designed to evenly coat both sides of spacer frames with Butyl.

KT-BM Series Butyl Extruder&Coating Machine For Insulating Glass Production

Introduction

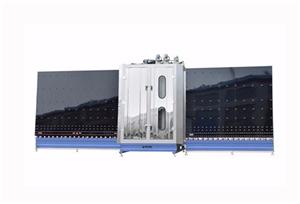

KT-BM01 Butyl Coating Machine

Features

The KT-BM01 butyl extruder for insulating glass produdction is controlled by PLC also with Photoelectric induction system to keep working more stable and accuracy.

Two rollers positioning to make aluminum bar transmission and coating more smooth and precise.

Hydraulic station with energy storage devices to keep machine with long working life.

The butyl extruder is vertical style Butyl cylinder design to keep great coating effect.

Technical parameters

| Model | KT-BM01 Butyl Coating Machine |

| Total Power | 4.75 KW |

| Adjustable Range | 4-16 mm |

| Squeeze Pressure | 10-17 Mpa |

| Working Speed | 0-35 m/min |

| Pistons Diameter | ∮170 mm |

| Air Pressure | 0.5-0.8 Mpa |

| Dimensions | 2600*600*1650 mm |

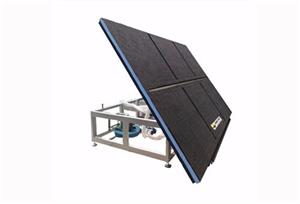

KT-BM02 Butyl Coating Machine

Features

Automatic control of nozzle width in application of pneumatic and hydraulic parallel method ,Possible to control a precise temperature and 1/100 sec interval of sensor perception.

Easily and quickly changeable of spacer width on a consecutive operation, Available to select a function for curved spacer, to control and operational height and conveyor belt speed(5 step).

Easily control able of all functions with Touch Screen and PLC program, Possible to control the length of Butyl application and monitoring current production quantity on Touch Screen.

Even coating on both sides of the frame, Continuously adjustable working height.

Processing of spacer frames with Georgian bars / muntin, Easy operation, Easy coating of round arches and shapes.

Technical parameters

| Model | KT-BM02 Butyl Coating Machine |

| Total Power | 3.75 KW |

| Adjustable Range | 4-18 mm |

| Squeeze Pressure | 10-15 Mpa |

| Working Speed | 0-35 m/min |

| Pistons Diameter | ∮200 mm |

| Air Pressure | 0.5-0.8 Mpa |

| Dimensions | 3000*600*950 mm |