Desiccant Dryer Filling Machine

- KING TECH

- CHINA

- 7 DAYS

- 300 SETS/MONTH

Full automatic on insulating glass production desiccant dryer filling. Include auto driller, auto filling and auto sealing for aluminum spacer.

Suitable any size, angle and width aluminum spacer.

PLC controller with Pneumatic pedal control to keep high accuracy and quality, also more safe and easy for staff.

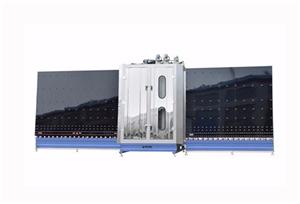

KT-F02 Desiccant Dryer Filling Machine for Insulating Glass Production

Introduction

KT-F02 Full Automatic Desiccant Filing Machine

Features

The KT-F02 automatic desiccant filling machine is on production of aluminum groove double-glazing glass, can finish necessary equipment for the molecular automatic filling. This machine structure, simple operation, advanced piece or more pieces can also filling.

The auto filling machine controlled by PLC system for the bending aluminum frame designed, filling in confined conditions, solve the problem of steam absorption of the molecular sieve, improve efficiency and lifetime of insulation glass. It is the necessary equipment for double glass production.

Drilling hole back and middle of the spacer, filling and sealing the hole automatic.

Both can use for bendable or unbendable aluminum spacer.

Filling height can be adjusted according to the size of the spacer frame.

Unique and advanced feeding device, automatic feeding.

Technical Parameters

| Model | KT-F02 Auto desiccant filling machine |

| Voltage | 220 V, 50/60 Hz |

| Total Power | 2.5 KW |

| Air Pressure | 0.5-0.8 Mpa |

| Flow Control | 24 g/s |

| Filling Speed | 8-12 s/piece |

| Size Error | ≤±0.05 mm |

| Total Weight | 400 kg |

| Dimensions | 1500×850×3650 mm |