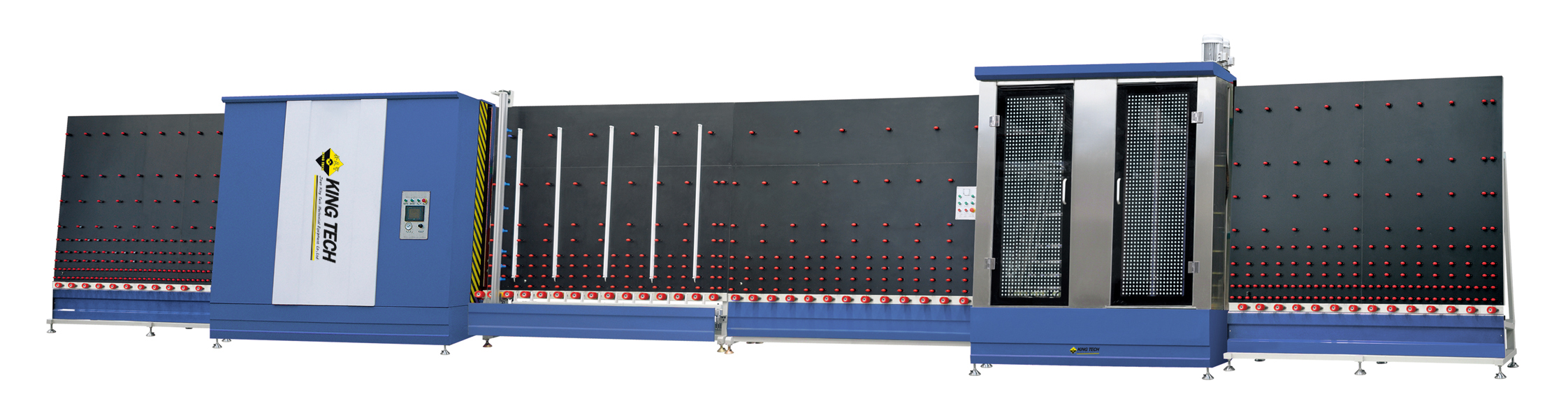

Full Automatic Insulating Glass Production Line

- KING TECH

- CHINA

- 15-25 DAYS

- 50 SETS/MONTH

Full automatic Insulating glass production line adopts the most advanced IG manufacture technology and craft in the world. It has all functions of inner-panel assembly and stepped glass process.

The line can process double unit,triple unit and step unit with high efficiency.The assembly optional auto gas filling press keeps both gas loss and cycle times low. At the end of the line, the sealing station ensures stability and above all perfect corners.Final auto seal machine perfect to finish whole insulating glass production to save much more time and cost on IG production.

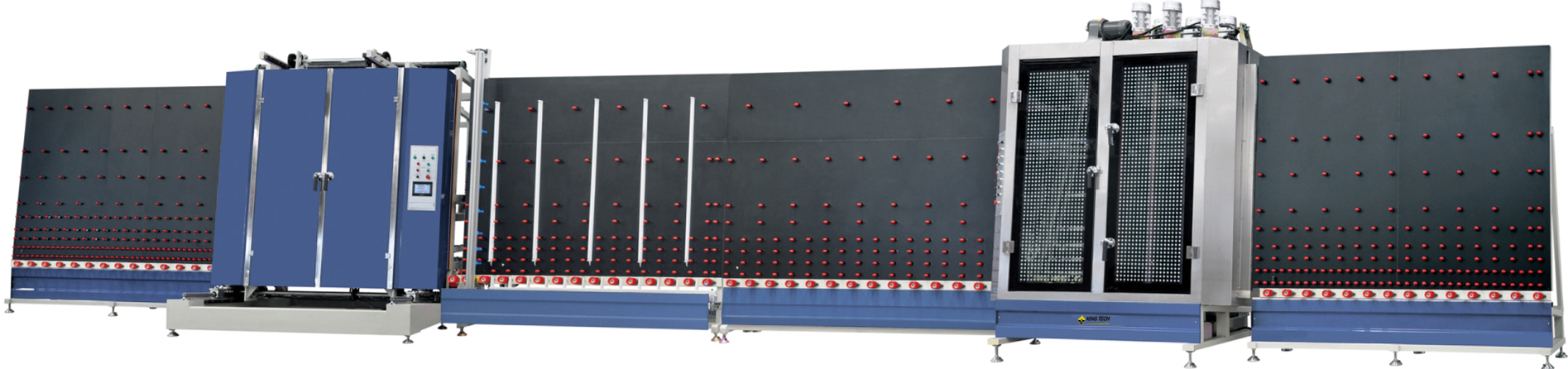

KT-IGL Series Full Automatic Insulating Glass Production Line

Introduction

IG Line WITH Sealing Robot

Features

The IG line with Sealing robot mostly suit for high standard IG unit production factory use. With high working performance and mass production.

This production line adopts the most advanced IG manufacture technology and craft in the world. It has all functions of inner-panel assembly and stepped glass process. This production line can process double unit,triple unit and step unit with high efficiency.The assembly optional auto gas filling press keeps both gas loss and cycle times low. At the end of the line, the sealing station ensures stability and above all perfect corners.Final auto seal machine perfect to finish whole insulating glass production to save much more time and cost on IG production.

The Full IG Line meeting wide-ranging requirements both high speed production and Mass intensive production. It is especially equipped for the production of coated insulating glass elements with aluminum spacers. The assembly and gas filling press keeps both gas loss and cycle times low. At the end of the line, the sealing station ensures stability and above all perfect corners.Final auto seal machine perfect to finish whole insulating glass production to save much more time and cost on IG production.

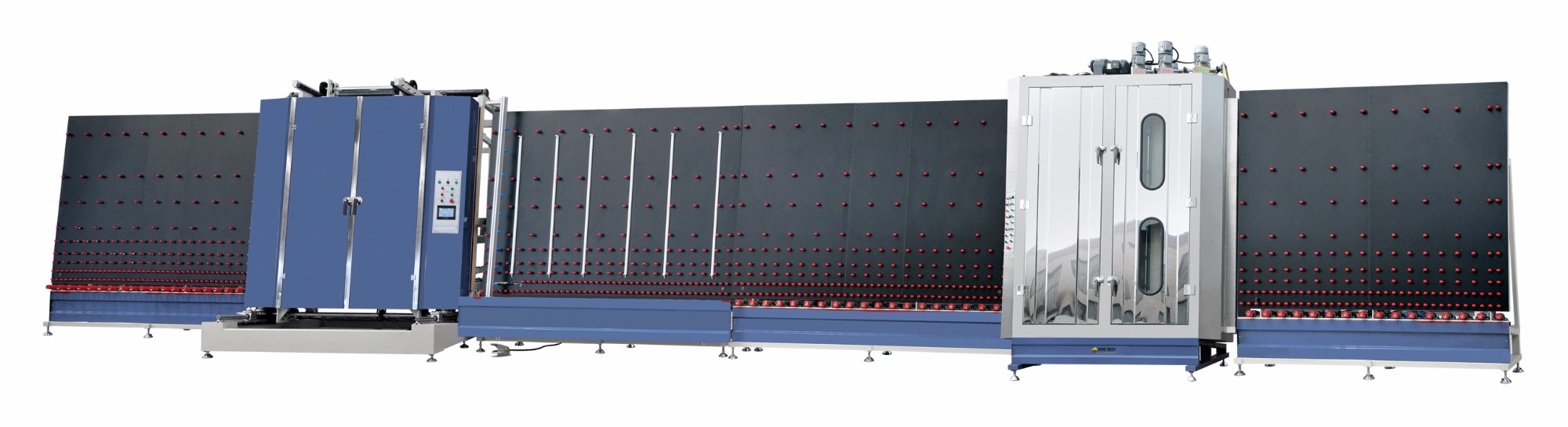

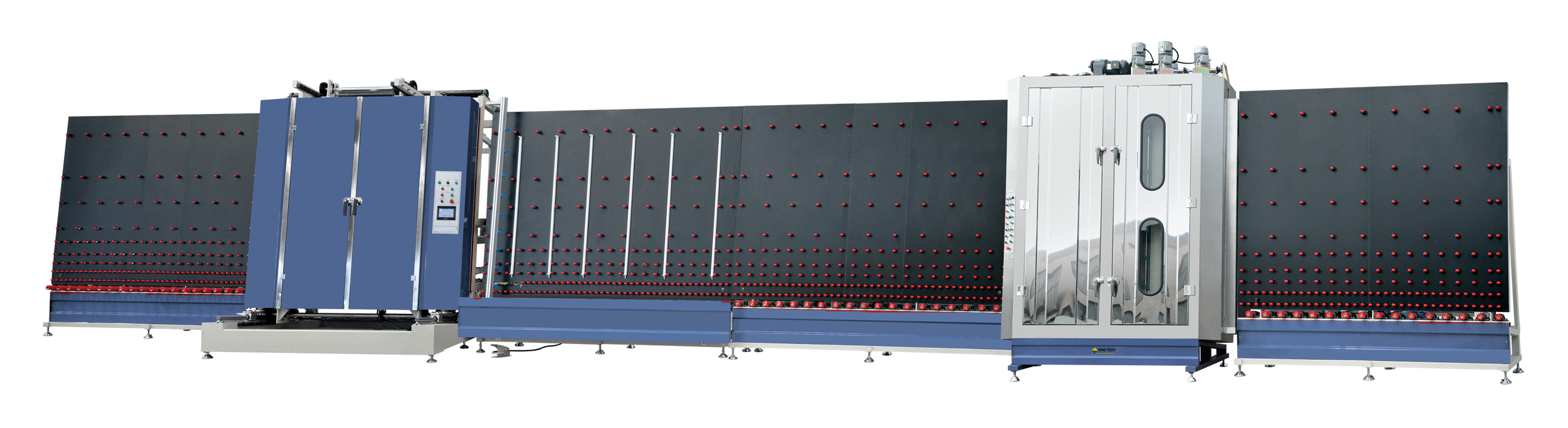

KT-IGL1600/1800 Full Automatic Insulating Glass Production Line(without sealing robot)

Section of Pressing Machine Features:

Italy Technical level of Production ,Installation and Mechanical.

Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass two or three pieces of glass or different sizes of glass .it adjust the size of different glass by motors to realize high auto and more exact running.

More practical and convenient design of pressing part about vacuum , pneumatic driving. It can deal with two or three pieces of glass and curtain walls .

There is mechanical position & adsorption device system from Taiwan to make it pressing on right position avoid displacement.

Reasonable hollow glass pressing process to keep all roller got much more longer life also avoid to break any glass.

The frame is welding by 2.75 mm International Rectangular pipe with high strength structure.

Section of Washing&Drying Machine Features:

Welding by stainless steel with high strength structure ; Top ceiling of it made by 12 mm Thickened stainless steel plate, the bottom is made by 5 mm thick stainless steel ,the lateral is made by 2 mm thick stainless steel.

There are four High temperature resistant brush with spray washing system to keep all clean process more easier , faster ,thorough and comprehensive.

All Spare parts in washing box is made by Stainless or Waterproof material to keep all section long and stable working life.

The Air drying system designed by air circle with naturally aspirated to keep all process more safe and cleaning.(Automatic air system could keep 40 ℃ of the blowing air).

It is Key-Link style of gear transmission to keep working in high accuracy.

Technical Parameters:

Model | KT-IGL1600 | KT-IGL1800 |

Input Voltage | 220/380/480 V 50/60 Hz | 220/380/480V 50/60 Hz |

Total Power | 13.5 KW | 15.5 KW |

Max Glass Size | 1600×2500 mm(custom) | 1800*2500 mm |

Min Glass Size | 300*400 mm | 300*400 mm |

Glass Thickness | 4-12 mm | 4-12 mm |

Working Speed | 4-48 m/min | 6-48 m/min |

Total Weight | 3300 kg | 3800 kg |

Size of Line(L×W×H) | 13500*2350*2450 mm | 15500*2350*2650 mm |

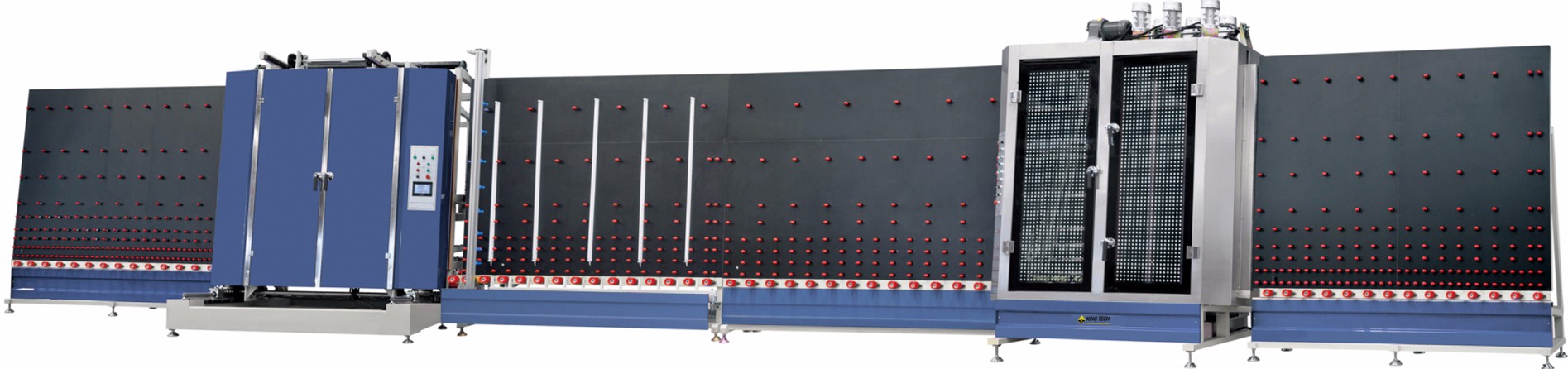

KT-IGL2000/2200 Full Automatic Insulating Glass Production Line(without sealing robot)

Section of Pressing Machine Features:

Italy Technical level of Production ,Installation and Mechanical.

Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.

More practical and convenient design of pressing part about vacuum , pneumatic driving. It can deal with two or three pieces of glass and curtain walls .

There is mechanical position & adsorption device system from Taiwan to make it pressing on right position avoid displacement.

Reasonable hollow glass pressing process to keep all roller got much more longer life also avoid to break any glass.

It could increase working speed as 45 m/min of glass to keep high efficiency (normally 900 pieces in 8 hours by different size insulating glass production).

The frame is welding by 2.75 mm International Rectangular pipe with high strength structure.

It is a completely automatic insulating glass production line (can produce LOW-E insulating glass).

2-monitor using system-Temperature/Speed/Production volume-Mechanical trouble check-Whole line control function with 1 monitor.

It realize glass pressing automatic inside the press machine. Press glass-normal insulted glass, triple and step insulated glass (selective)and curtain wall glass and abnormity insulated glass.

Full distance automatic changeable frequency speed adjustment, which can save work waiting time and improve production efficiency.

Press board can open, easy to examine an repair.

When insulating glass is pressed, the front and back part of pressing machine will up the glass with lever-type arm and hand system,(mechanical position +mobile sucking system)all this will ensure no malposition.

Section of Washing&Drying Machine Features:

Welding by stainless steel with high strength structure ; Top ceiling of it made by 12 mm Thickened stainless steel plate, the bottom is made by 5 mm thick stainless steel ,the lateral is made by 2 mm thick stainless steel.

There are four High temperature resistant brush with spray washing system to keep all clean process more easier , faster ,thorough and comprehensive.

All Spare parts in washing box is made by Stainless or Waterproof material to keep all section long and stable working life.

The Air drying system designed by air circle with naturally aspirated to keep all process more safe and cleaning.(Automatic air system could keep 40 ℃ of the blowing air).

It is Key-Link style of gear transmission to keep working in high accuracy.

Inside part of wash machine, dry machine and the air dryer are both stainless steel production.It is elegant appearance and never rust.

Germany Imported Brush, got High temperature, anti-static function.

Technical Parameters:

Model | KT-IGL2000 | KT-IGL2200 |

Input Voltage | 220/380/480 V 50/60 Hz | 220/380/480 V 50/60 Hz |

Total Power | 19.5 KW | 23.5 KW |

Max Glass Size | 2000×2500 mm | 2200×3000 mm |

Min Glass Size | 300×450 mm | 300×450 mm |

Glass Thickness | 4-18 mm | 4-18 mm |

Working Speed | 8-48 m/min | 8-48 m/min |

Total Weight | 4500 kg | 4900 kg |

Size of Line(L×W×H) | 17000*2660*3030 mm | 18500*2660*3530 mm |

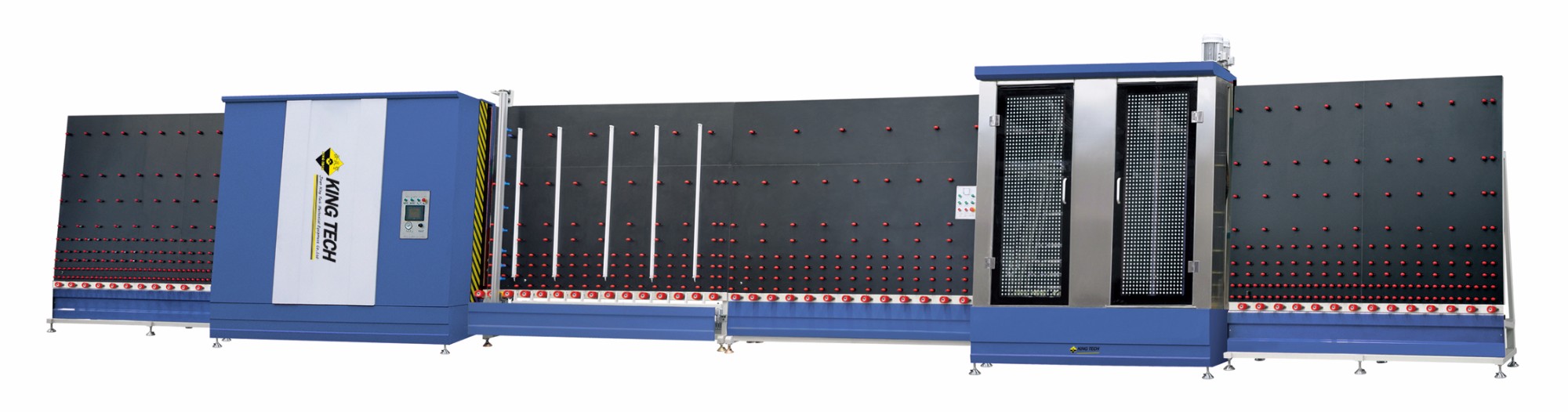

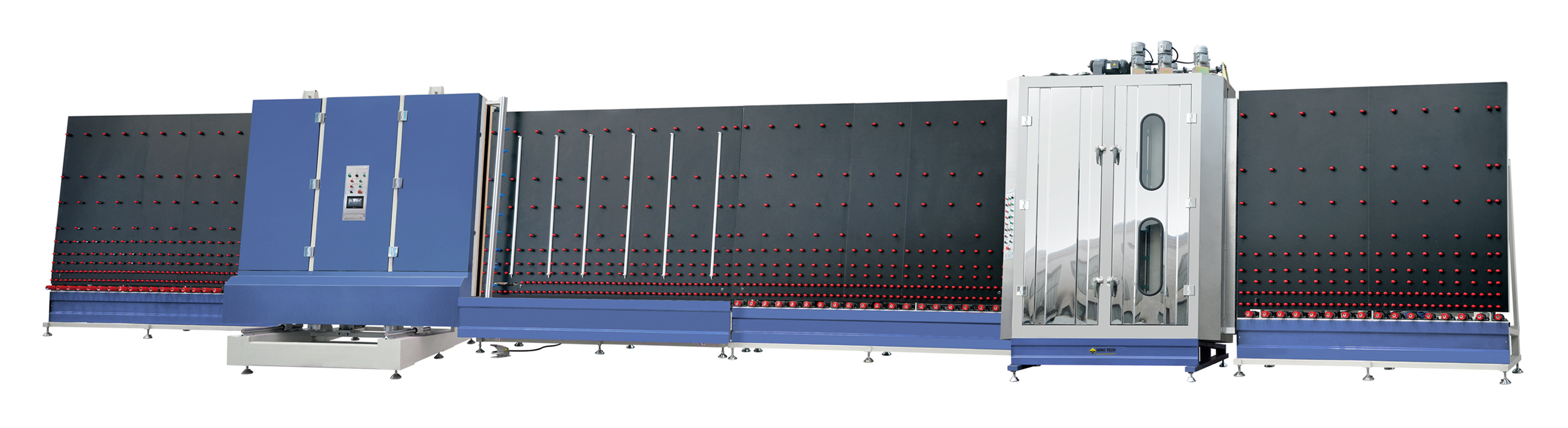

KT-IGL2500 Full Automatic Insulating Glass Production Line(without sealing robot)

Section of Pressing Machine Features:

Italy Technical level of Production ,Installation and Mechanical.

Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.

More practical and convenient design of pressing part about vacuum , pneumatic driving. It can deal with two or three pieces of glass and curtain walls .

There is mechanical position & adsorption device system from Taiwan to make it pressing on right position avoid displacement.

Reasonable hollow glass pressing process to keep all roller got much more longer life also avoid to break any glass.

It could increase working speed as 45 m/min of glass to keep high efficiency (normally 900 pieces in 8 hours by different size insulating glass production).

The frame is welding by 2.75 mm International Rectangular pipe with high strength structure.

It is a completely automatic insulating glass production line (can produce LOW-E insulating glass).

2-monitor using system-Temperature/Speed/Production volume-Mechanical trouble check-Whole line control function with 1 monitor.

It realize glass pressing automatic inside the press machine. Press glass-normal insulted glass, triple and step insulated glass (selective)and curtain wall glass and abnormity insulated glass.

Full distance automatic changeable frequency speed adjustment, which can save work waiting time and improve production efficiency.

Press board can open, easy to examine an repair.

When insulating glass is pressed, the front and back part of pressing machine will up the glass with lever-type arm and hand system,(mechanical position +mobile sucking system)all this will ensure no malposition.

Section of Washing&Drying Machine Features

Welding by stainless steel with high strength structure ; Top ceiling of it made by 12 mm Thickened stainless steel plate, the bottom is made by 5 mm thick stainless steel ,the lateral is made by 2 mm thick stainless steel.

There are four Six temperature resistant brush with spray washing system to keep all clean process more easier , faster ,thorough and comprehensive.

All Spare parts in washing box is made by Stainless or Waterproof material to keep all section long and stable working life.

The Air drying system designed by air circle with naturally aspirated to keep all process more safe and cleaning.(Automatic air system could keep 40 ℃ of the blowing air).

It is Key-Link style of gear transmission to keep working in high accuracy.

Inside part of wash machine, dry machine and the air dryer are both stainless steel production.It is elegant appearance and never rust.

Technical Parameters:

Model | GPL-XY2500Y |

Input Voltage | 220/380/480 V 50/60 Hz |

Total Power | 28.5 KW |

Max Glass Size | 2500x3000 mm |

Min Glass Size | 300×450 mm |

Glass Thickness | 4-18 mm |

Working Speed | 8-48 m/min |

Total Weight | 5500 kg |

Size of Line(L×W×H) | 18500*2850*3530 mm |

KT-IGL2500/2000-GF Automatic Gas Filling Insulating Glass Production Line(without sealing robot)

Section of Flat Press:

Italy Technical level of Production ,Installation and Mechanical. Auto Gas Filling Function.

Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.

More practical and convenient design of pressing part about vacuum , pneumatic driving. It can deal with two or three pieces of glass and curtain walls .

There is mechanical position & adsorption device system from Taiwan to make it pressing on right position avoid displacement.

Reasonable hollow glass pressing process to keep all roller got much more longer life also avoid to break any glass.

It could increase working speed as 45 m/min of glass to keep high efficiency (normally 900 pieces in 8 hours by different size insulating glass production).

The frame is welding by 2.75 mm International Rectangular pipe with high strength structure.

It is a completely automatic insulating glass production line (can produce LOW-E insulating glass).

2-monitor using system-Temperature/Speed/Production volume-Mechanical trouble check-Whole line control function with 1 monitor.

It realize glass pressing automatic inside the press machine. Press glass-normal insulted glass, triple and step insulated glass (selective)and curtain wall glass and abnormity insulated glass.

Full distance automatic changeable frequency speed adjustment, which can save work waiting time and improve production efficiency.

Press board can open, easy to examine an repair.

When insulating glass is pressed, the front and back part of pressing machine will up the glass with lever-type arm and hand system,(mechanical position + mobile sucking system)all this will ensure no malposition.

Section of Washing&Drying Machine:

Welding by stainless steel with high strength structure ; Top ceiling of it made by 12 mm Thickened stainless steel plate, the bottom is made by 5 mm thick stainless steel ,the lateral is made by 2 mm thick stainless steel.

There are Six High temperature resistant brush with spray washing system to keep all clean process more easier , faster ,thorough and comprehensive.

All Spare parts in washing box is made by Stainless or Waterproof material to keep all section long and stable working life.

The Air drying system designed by air circle with naturally aspirated to keep all process more safe and cleaning.(Automatic air system could keep 40 ℃ of the blowing air).

It is Key-Link style of gear transmission to keep working in high accuracy.

Inside part of wash machine, dry machine and the air dryer are both stainless steel production.It is elegant appearance and never rust.

Technical Parameters:

Model | KT-IGL2000-GF | KT-IGL2500-GF |

Input Voltage | 220/380/480 V 50/60 Hz | 220/380/480 V 50/60 Hz |

Total Power | 19.5 KW | 25 KW |

Max Glass Size | 2000×2500 mm | 2000×3500 mm |

Min Glass Size | 300×450 mm | 300×450 mm |

Glass Thickness | 4-18 mm | 4-18 mm |

Working Speed | 8-48 m/min | 8-48 m/min |

Total Weight | 5200 kg | 6000 kg |

Size of Line(L×W×H) | 18000*2660*3030 mm | 19500*2660*3530 mm |